Have you lost sight of risk in your workplace?

Proactive Risk Management

Your Data-Driven Defense Against Risk

Proactively Identify, Analyze and Eliminate Risk

1

Conduct Risk Analysis

- Identify and document all your potential risks

- Conduct basic, advanced, or root cause analyses

- Apply your preferred risk assessment methodology (e.g., JHA, HAZOP)

- Communicate your findings to relevant users and departments

2

Qualify Risk

- Evaluate and categorize your risks on a scale

- Prioritize specific risks to implement necessary preventive measures

3

Take Corrective and Preventive Action

- Initiate and track your corrective and preventive actions, tasks, or entire projects

- Ensure accountability by assigning ownership based on roles, groups, or individuals

- Gain a centralized overview of all your data sources and modules

- Generate daily task reports

4

Analyze and Report

- Enable flexible reporting

- Track and measure data against your safety KPI performance

- Record and report your risks to regulators to ensure compliance

- Gain insight into your risk trends and devise preventive plans to avoid them

Prioritize Safety. Drive Productivity. Reach Your Goals.

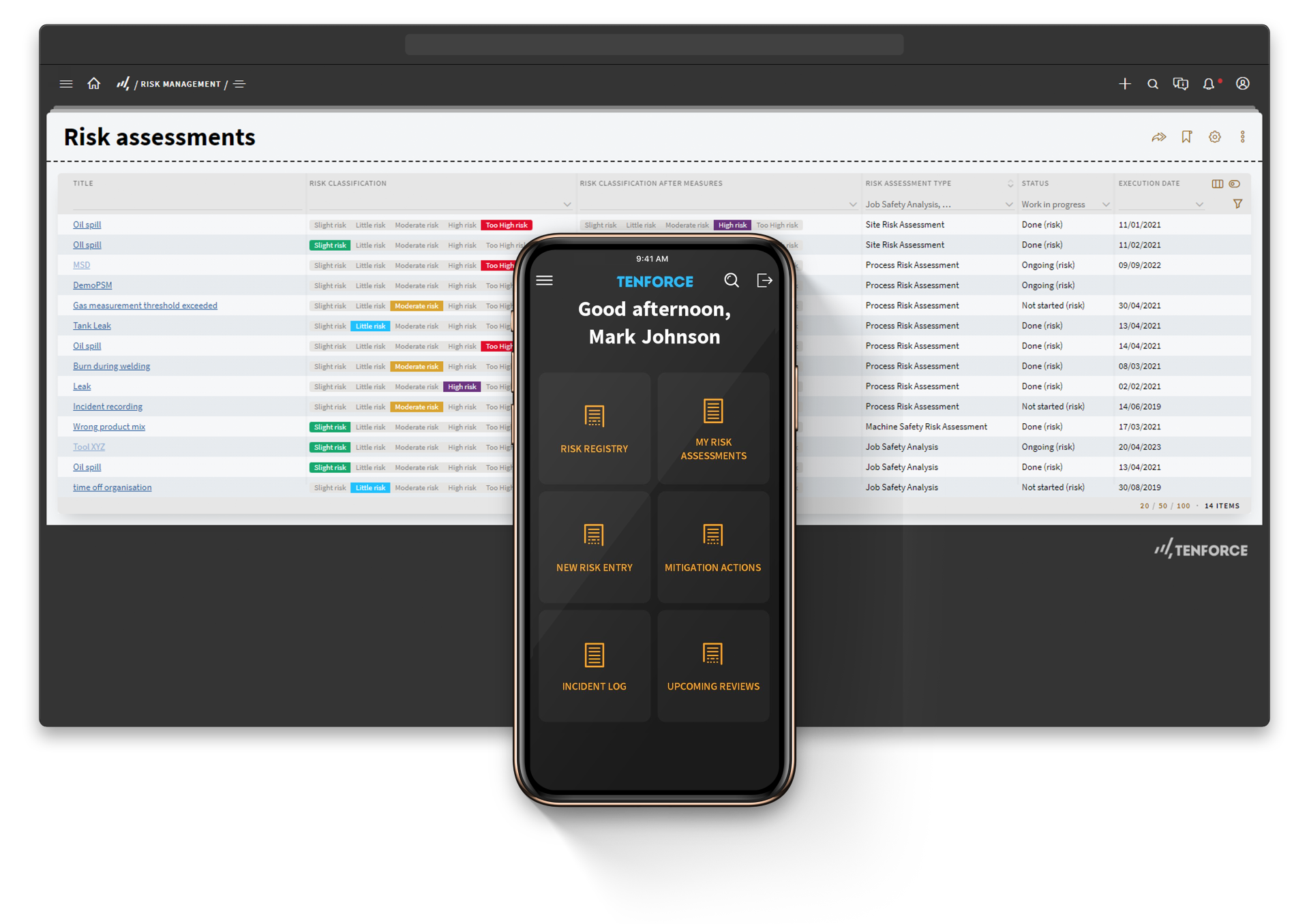

Gain Visibility through a Centralized Platform

- Take command of your risk management with a clear overview

- Make better decisions with improved visibility of risk across your organization

- Achieve a holistic approach to Health, Safety, and Environment by integrating with other modules

Unlock Real-Time Insights and Reporting

- Drive decision-making with real-time data and interactive dashboards

- Respond rapidly to incidents with instant alerts and notifications

- Measure the tangible impact of your risk prevention strategy with ROI calculations

Simplify Compliance Management

- Maintain a transparent audit trail

- Generate regulatory reports to streamline compliance management

- Adhere to ISO, OSHA, and other regulatory standards

Streamline Workflows and Automate Processes

- Leave manual tasks behind with automated data capture and tracking

- Boost efficiency and effectiveness with logical, streamlined workflows

- Guarantee accuracy and consistency with swift approval and validation processes

- Free up your team for critical tasks and functions

25%

faster identification and mitigation of potential risks

20%

reduction in incidents stemming from previously unidentified risks

Seamlessly integrate with other TenForce modules to unify your EHSQ processes

Audits & Inspections

Incident Management

LoTo

Permit to Work

Management of Change

Shift Management

Risk Management

Competence management

Quality management

Contractor Management

SAFETY DATASHEETS

MECHANICAL INTEGRITY

Document control

Complaint Handling

Environmental Management

CAPA

Environmental reporting

Compliance calendar

Dive deeper into this topic

Mapping Daily Workplace Hazards and Technology to Reduce Risk

The National Safety Council has an ambitious target — to eliminate workplace fatalities by 2050 through the adoption of emerging technology. As part of their “Work to Zero” initiative, they have identified the most common workplace hazards for heavy industry workers and the recommended technologies to reduce risk. Below we’ve selected some of the most common ones in the manufacturing industry:

Hot work – any activity that creates flame, heat or sparks (e.g.…

8 Do’s and Don’ts for Successful Risk Management (+ our Pro Tip!)

Risk – it’s a constant presence in our lives. But while it’s true that risks are always present, how we manage and mitigate them serves as the true measure of our operational success.

Welcome to the world of risk management. Here, the goal is clear: identify, assess, and mitigate the array of potential hazards that could occur in your operations. To help you along, we share a list of eight crucial do’s and don’ts for a finely tuned risk management process.…

Your peers trust us

Our customers rely on TenForce to foster a proactive safety culture and drive continuous process improvement. The outcome? Increased team efficiency, reduced administrative burden, and significant cost savings due to fewer fines and incident-related downtime.

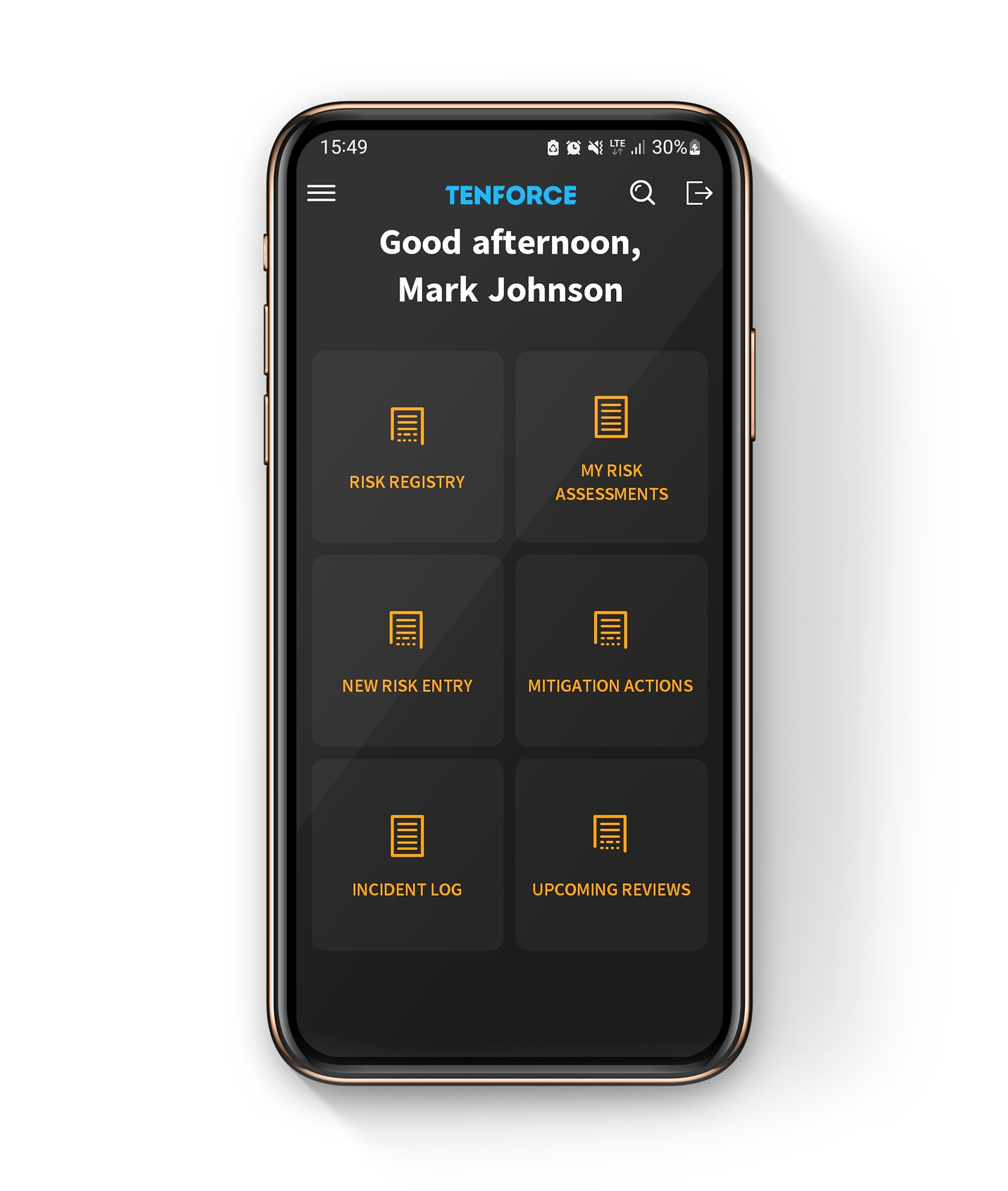

Book a demo

Curious to see how TenForce can make your workday easier? Book a demo, and we’ll show you what our EHSQ platform can do! One of our in-house experts will guide you through the ins and outs, showing you exactly how TenForce can tackle your challenges, whether it’s managing safety, streamlining compliance, or keeping quality in check.

So, choose a time that works for you, and let’s explore how TenForce fits into your day-to-day.

Ask us questions. Get clear answers. Share the recording with your colleagues.