Are you struggling to keep track of hazardous chemicals in your facility?

Accessible Safety Data Sheets

Find Critical Safety Information Quickly

Track the entire chemical lifecycle, from procurement to disposal

1

Identify and map hazards

- Collect comprehensive data on chemical composition, hazards, handling procedures, and regulatory requirements

- Enter data in a structured way, detailing hazard information and precautions

2

Generate, review and distribute SDSs

- Generate safety data sheets that comply with regulations like OSHA's HCS or GHS

- Review documents for accuracy and completeness before approving

- Distribute SDSs electronically to relevant stakeholders

- Provide easy access and comply with record-keeping requirements

3

Store and maintain documents

- Map hazards linked to chemicals and find what you're looking for quickly with advanced filter and search functions

- Provide access to original SDS documents, track changes, manage versions, and identify obsolete versions promptly

- Automate updates and revisions to keep SDS documents current and compliant

4

Manage suppliers

- Keep detailed records of hazardous chemicals from suppliers

- Enter data in a structured way, detailing hazard information and precautions

- Analyze, support, automate, and monitor compliance processes and provisions

Access chemical information in just a few clicks

Manage your chemical inventory with confidence

Simplify your chemical inventory and log new products to assess potential hazards. Maintain an overview of all chemicals on site and automate tracking from procurement to disposal.

Stay up to date with REACH and other regulatory requirements.

Keep your SDS library up to date

Keep safety data sheets current and organized, adding new chemical information with ease. Use custom tags to quickly find what you need and access crucial information anytime, anywhere.

Stay on top of updates with automatic reminders.

Reduce risks with safety precautions

Make your SDS library easily accessible to all employees so they can quickly find safety information and conduct risk assessments.

Update obsolete safety data sheets promptly to reduce accidents and injuries.

Seamlessly integrate with other TenForce modules to unify your EHSQ processes

Audits & Inspections

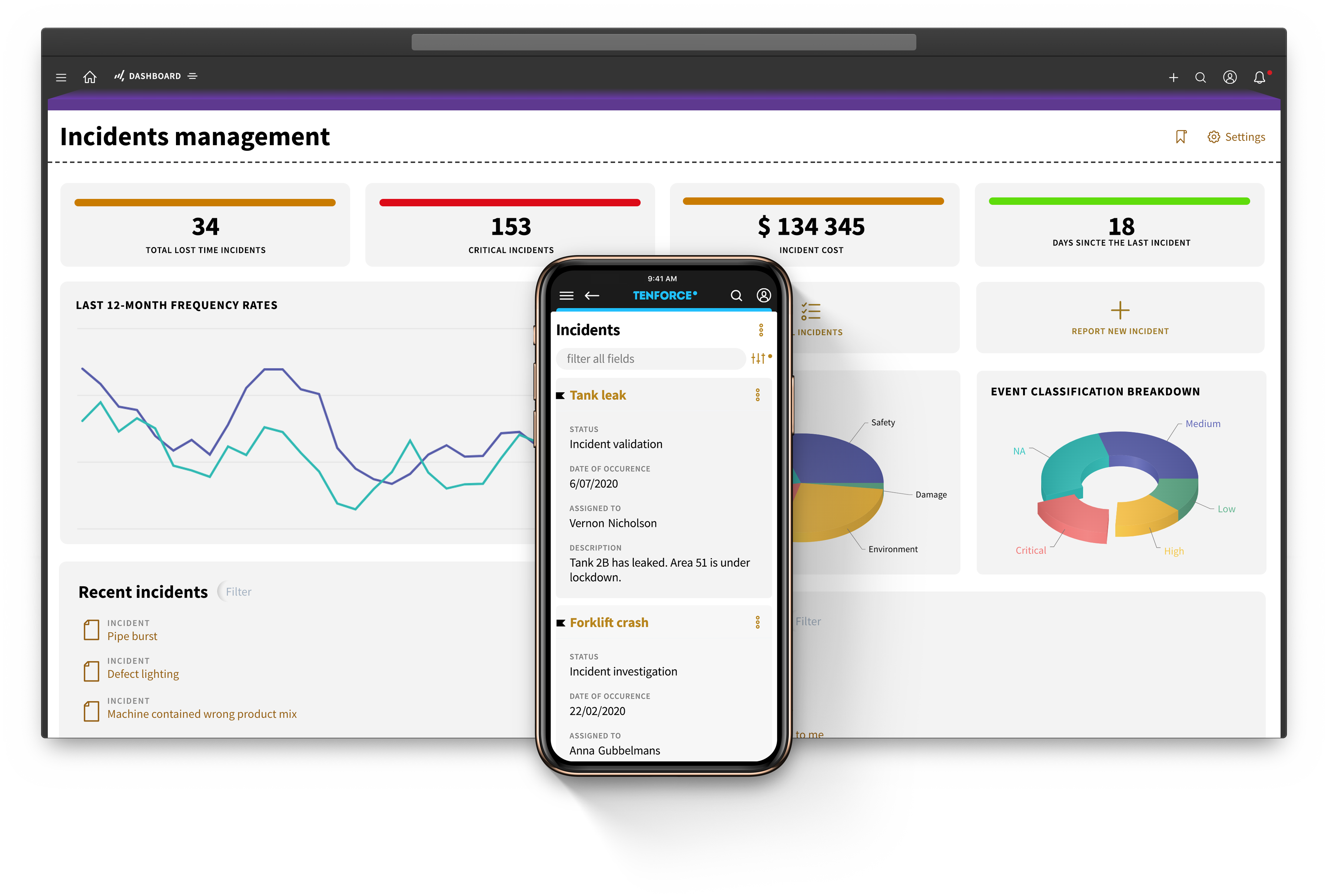

Incident Management

LoTo

Permit to Work

Management of Change

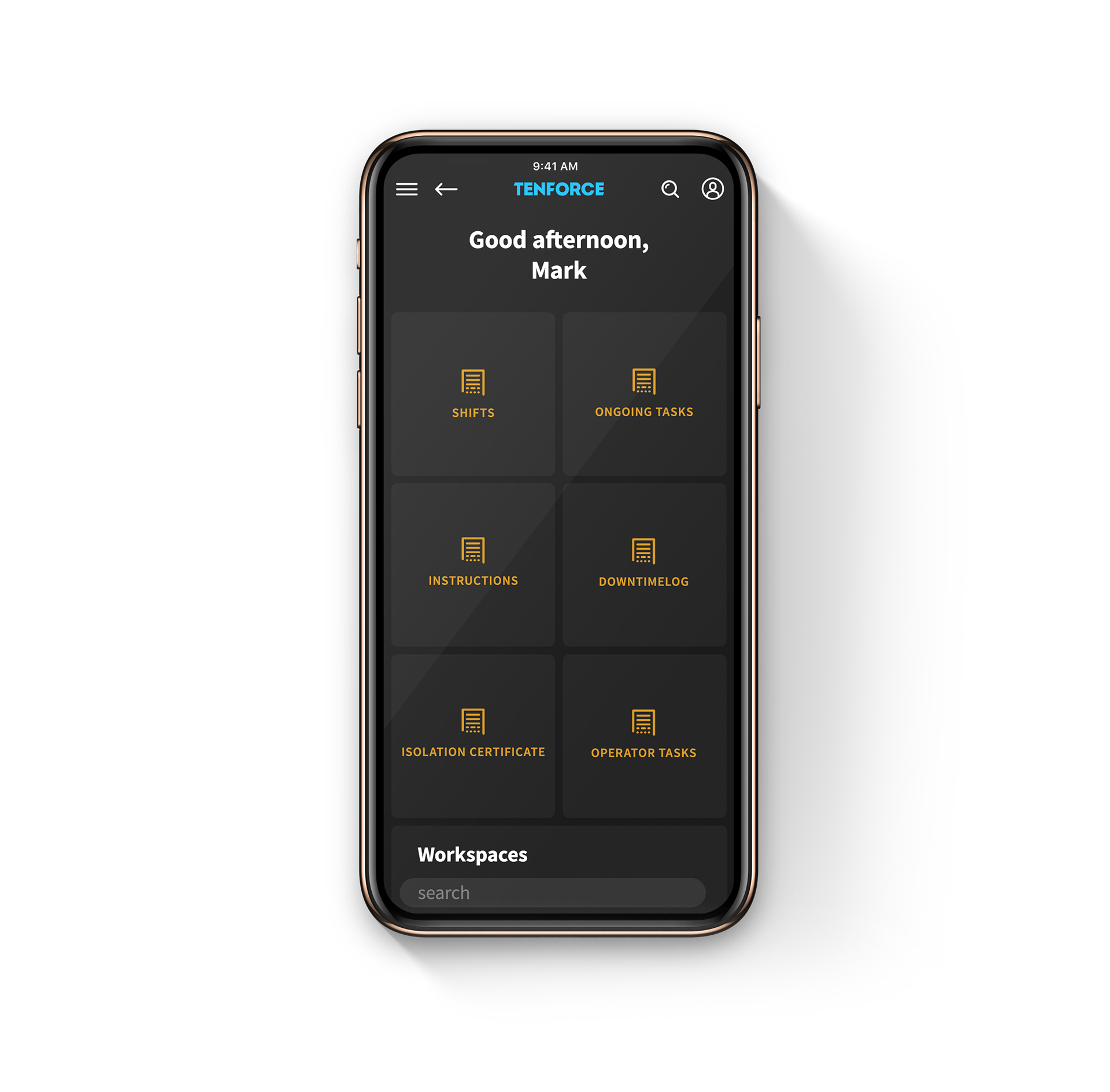

Shift Management

Risk Management

Competence management

Quality management

Contractor Management

SAFETY DATASHEETS

MECHANICAL INTEGRITY

Document control

Complaint Handling

Environmental Management

CAPA

Environmental reporting

Compliance calendar

Dive deeper into this topic

How TenForce Helps You Prove Compliance with Responsible Care®

Meeting Responsible Care® requirements isn’t just about following best practices—it’s about being able to prove that you do. That’s why the American Chemistry Council (ACC) requires members to implement a Responsible Care® management system and demonstrate compliance through documentation, audits, and continuous improvement.

TenForce makes this easier. Our unified EHSQ system brings everything together—so you can track safety measures, document environmental responsibility, and prove compliance with Responsible Care® at every step.…

TenForce & AIAS Supporting EHS Professionals in Italy

[EN translation below]

In TenForce, il nostro obiettivo è rendere il lavoro degli HSE più semplice e più efficiente—riducendo i rischi, semplificando la conformità e, soprattutto, facilitandoti la vita. Ecco perché siamo entusiasti di collaborare con AIAS, la principale associazione italiana per salute e sicurezza.

Chi è AIAS?Dal 1975, AIAS (Associazione Italiana Ambiente e Sicurezza) aiuta le aziende a creare una forte cultura della sicurezza. Connettono i professionisti EHS di tutta Italia, offrendo formazione, risorse e competenze tecniche su tematiche come la prevenzione dei rischi e la sostenibilità. …

What Chemical and Energy Leaders in Texas Can Teach Us About Zero-Incident Operations

Kuraray, Ascend, Kaneka, and Phillips 66—four chemical and energy giants operating in our Houston backyard. They manufacture everything from specialty chemicals to petroleum products, navigating hazardous materials, extreme temperatures, and heavy machinery daily. Yet, despite the risks, they share one goal: zero incidents.

How do they make safety second nature? Here’s what we can learn from the best in the chemicals, materials, and energy industries.

Keep talking about safetyToolbox talks, shift handovers, and pre-job safety meetings are great, but they’re not the only moments for safety discussions.…

How to Fit Safety Training into a Busy Schedule with Self-Paced Learning

Untrained employees, heavy machinery, and hazardous chemicals—it’s an accident waiting to happen. Knowing the risks and how to manage them is essential for the safety of everyone on-site, but training in busy workplaces isn’t always easy. Christophe Jacobs, Chief Customer Success Officer at FLOWSPARKS shares how digital, self-paced learning can improve safety for employees and contractors. And how, thanks to the integration of FLOWSPARKS with TenForce’s Competence Management, training is easy to create, follow, and track.…

Your peers trust us

Our customers rely on TenForce to foster a proactive safety culture and drive continuous process improvement. The outcome? Increased team efficiency, reduced administrative burden, and significant cost savings due to fewer fines and incident-related downtime.

Book a demo

Curious to see how TenForce can make your workday easier? Book a demo, and we’ll show you what our EHSQ platform can do! One of our in-house experts will guide you through the ins and outs, showing you exactly how TenForce can tackle your challenges, whether it’s managing safety, streamlining compliance, or keeping quality in check.

So, choose a time that works for you, and let’s explore how TenForce fits into your day-to-day.

Ask us questions. Get clear answers. Share the recording with your colleagues.