Are you struggling to keep track of hazardous chemicals in your facility?

Accessible Safety Data Sheets

Find Critical Safety Information Quickly

Track the entire chemical lifecycle, from procurement to disposal

1

Identify and map hazards

- Collect comprehensive data on chemical composition, hazards, handling procedures, and regulatory requirements

- Enter data in a structured way, detailing hazard information and precautions

2

Generate, review and distribute SDSs

- Generate safety data sheets that comply with regulations like OSHA's HCS or GHS

- Review documents for accuracy and completeness before approving

- Distribute SDSs electronically to relevant stakeholders

- Provide easy access and comply with record-keeping requirements

3

Store and maintain documents

- Map hazards linked to chemicals and find what you're looking for quickly with advanced filter and search functions

- Provide access to original SDS documents, track changes, manage versions, and identify obsolete versions promptly

- Automate updates and revisions to keep SDS documents current and compliant

4

Manage suppliers

- Keep detailed records of hazardous chemicals from suppliers

- Enter data in a structured way, detailing hazard information and precautions

- Analyze, support, automate, and monitor compliance processes and provisions

Access chemical information in just a few clicks

Manage your chemical inventory with confidence

Simplify your chemical inventory and log new products to assess potential hazards. Maintain an overview of all chemicals on site and automate tracking from procurement to disposal.

Stay up to date with REACH and other regulatory requirements.

Keep your SDS library up to date

Keep safety data sheets current and organized, adding new chemical information with ease. Use custom tags to quickly find what you need and access crucial information anytime, anywhere.

Stay on top of updates with automatic reminders.

Reduce risks with safety precautions

Make your SDS library easily accessible to all employees so they can quickly find safety information and conduct risk assessments.

Update obsolete safety data sheets promptly to reduce accidents and injuries.

Seamlessly integrate with other TenForce modules to unify your EHSQ processes

Audits & Inspections

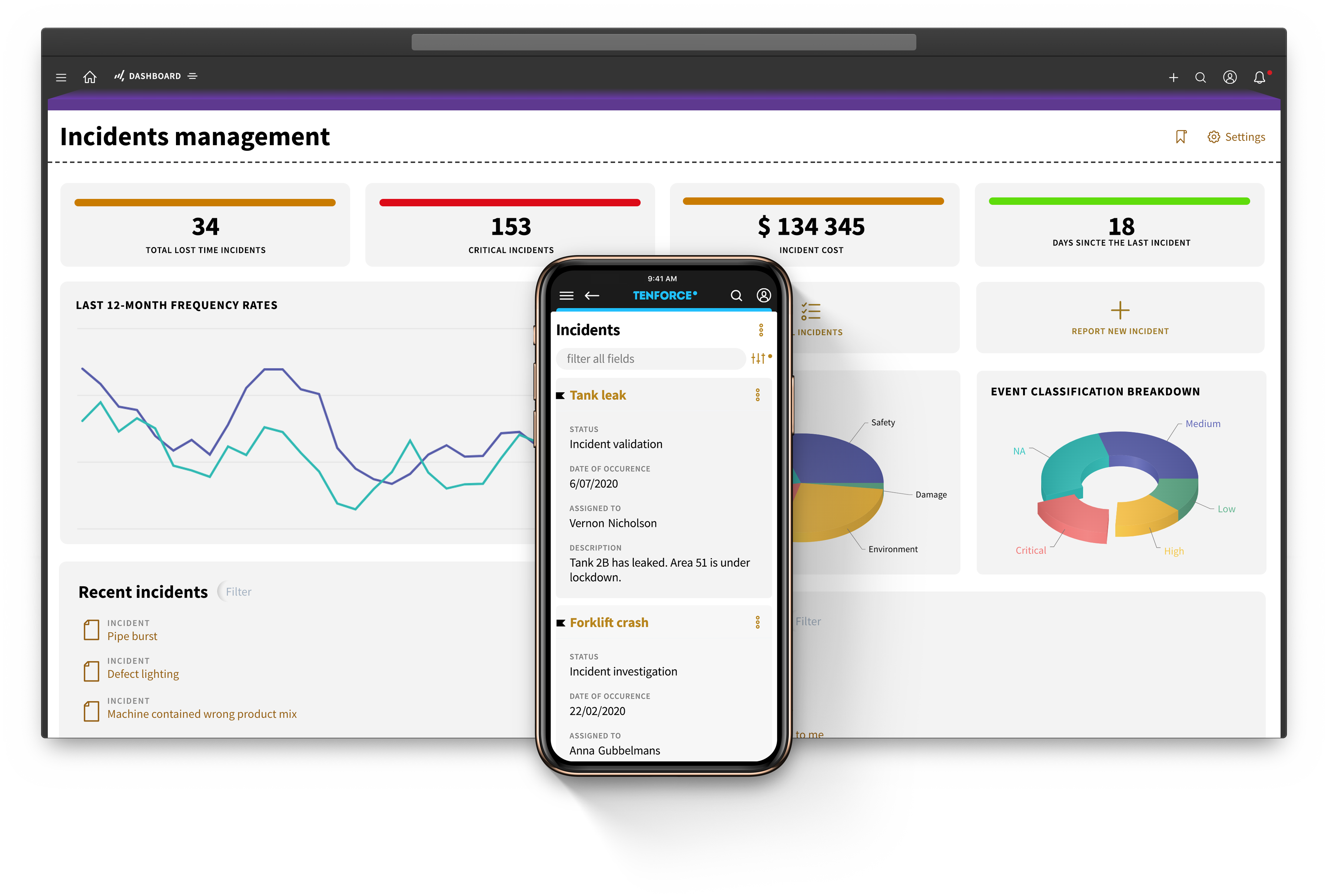

Incident Management

LoTo

Permit to Work

Management of Change

Shift Management

Risk Management

Competence management

Quality management

Contractor Management

SAFETY DATASHEETS

MECHANICAL INTEGRITY

Document control

Complaint Handling

Environmental Management

CAPA

Environmental reporting

Compliance calendar

Dive deeper into this topic

EHS Regulatory Changes in Belgium and the Netherlands to Watch in 2026 (+ Your Practical Readiness Checklist)

In 2026 (just like any other year), if you’re an EHS professional at a high-risk site in Belgium or the Netherlands, there are plenty of regulatory changes to keep up to date with. PFAS rules converge. Exposure limits drop. Permitting becomes less forgiving. Documentation that “has always been fine” suddenly needs to be reviewed.

Sometimes the challenge is knowing these regulations exist or have changed. But often, the real difficulty is knowing where they touch your site and turning that knowledge into concrete actions before inspections, projects, or shutdowns force the issue.…

From Safety Culture to AI: Inside The Future Is WOW 2025

What do Lamot Mechelen, De Koninck, and De Hoorn have in common? They’ve all hosted The Future Is WOW. And yes — they’re all breweries. It’s less a coincidence and more who we are at this point. We could pretend it’s because we love “brewing ideas,” “crafting partnerships,” or “tapping into your insights,” but honestly? We just enjoy a bit of old-fashioned hops-pitality. (Don’t worry, that’s the last pun. Probably.)

This year felt especially close to home.…

TenForce Is ISO 27001 Certified and It’s Good News for Your Team

As TenForce’s Quality Assurance Manager, I spend a lot of time working with customers, auditors, and internal teams. Over the past few years, one request kept coming up: “Do you have ISO 27001?”

That’s why I’m writing this.

Every day, your teams capture information that keeps your operations safe and compliant. It’s detailed, sensitive, and essential to your business. When you share that data with us, we treat it with the care it deserves. …

Putting Safety at the Heart of Texas Industry

When I moved to Houston, Texas just over a year ago, one thing stood out right away: the sheer scale of Texas industry.

From the steel mills of Midlothian to the petrochemical hubs of Houston, Baytown, and Freeport, this region doesn’t just power the U.S., it makes products that keep the world running.

Inside these massive, high-risk sites, the work never really stops. Every shift brings new challenges: controlling process safety risks, maintaining compliance across thousands of procedures, and protecting people in environments where one small mistake can have serious consequences. …

Your peers trust us

Our customers rely on TenForce to foster a proactive safety culture and drive continuous process improvement. The outcome? Increased team efficiency, reduced administrative burden, and significant cost savings due to fewer fines and incident-related downtime.

Book a demo

Curious to see how TenForce can make your workday easier? Book a demo, and we’ll show you what our EHSQ platform can do! One of our in-house experts will guide you through the ins and outs, showing you exactly how TenForce can tackle your challenges, whether it’s managing safety, streamlining compliance, or keeping quality in check.

So, choose a time that works for you, and let’s explore how TenForce fits into your day-to-day.

Ask us questions. Get clear answers. Share the recording with your colleagues.