Manual processes slowing you down and paperwork getting out of hand?

Transformational Quality Management

From Compliance to Competitive Edge

Meeting the Diverse Needs of Quality and Compliance Managers

Effortless Audits

Maintain a consistent workflow, swiftly retrieve necesssary documentation, and track findings with precision.

No More Recalls

Mitigate potential risks, report incidents, identify root causes, and track CAPA plans to completion.

Delight Your Customers

Intercept and eliminate issues before they reach customers. Address and resolve customer feedback promptly.

Uphold Compliance

Master ever-changing industry regulations, adeptly handle change, and maintain compliant document control

Elevate Your Brand

Increase operational effiency and deliver consistently high customer service to build your reputation for exceptional quality.

Process Documentation That Demonstrates IS0 9001 Compliance

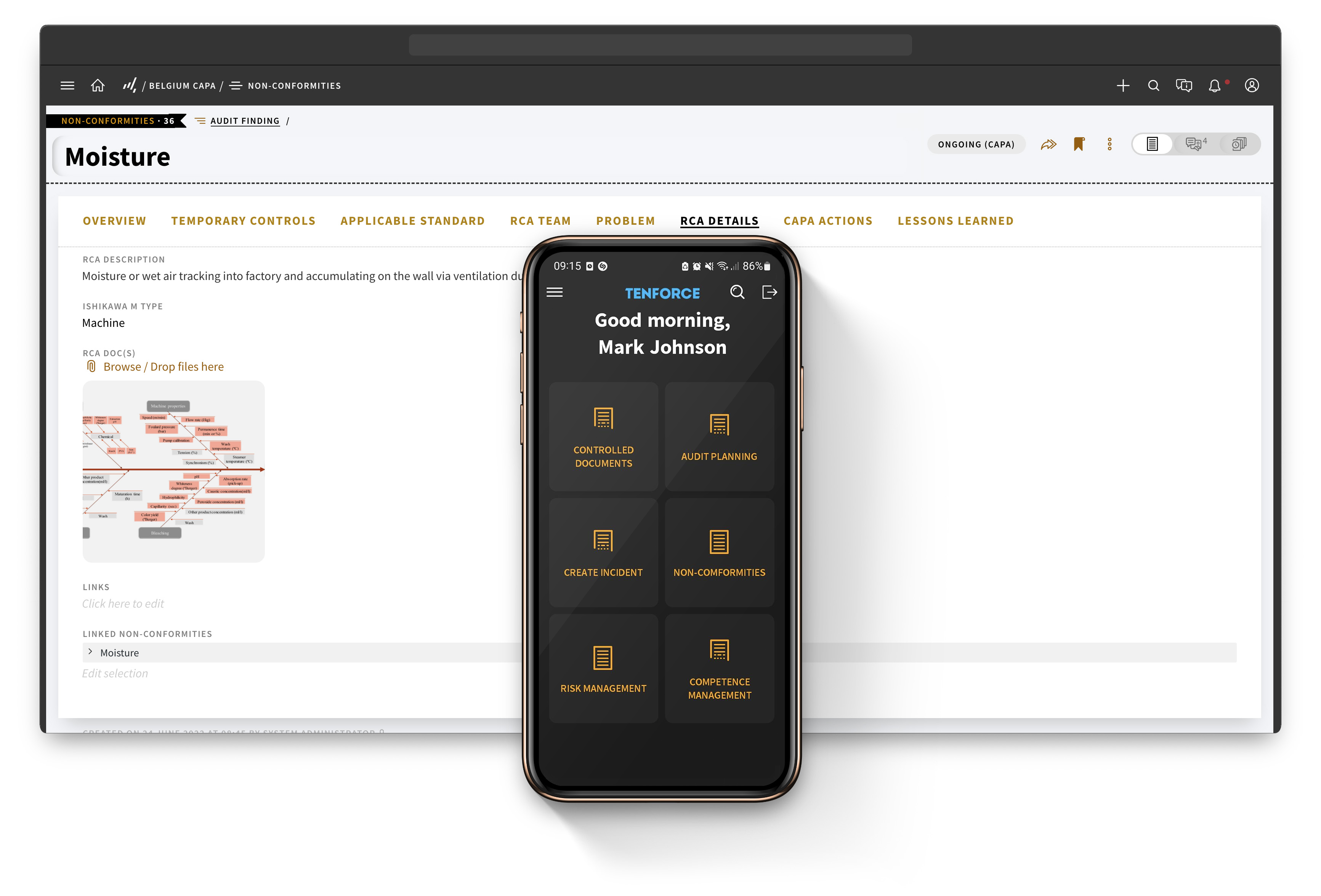

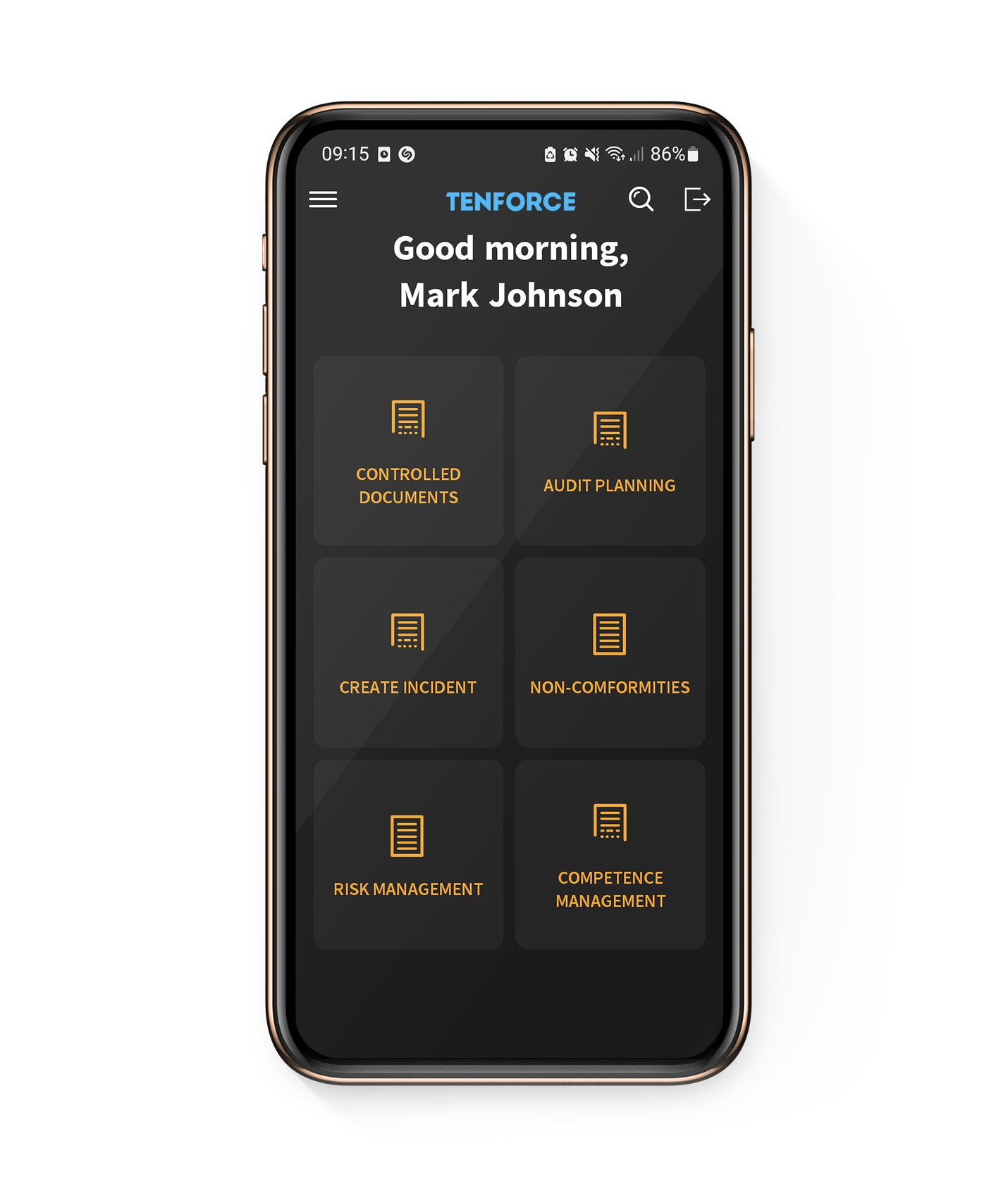

From Dispersed Data to Decisive Action

Streamline data capture from diverse processes to increase visibility, perform insightful analysis and make data-driven decisions.

Consistent Processes = Swift Responses

Automate alerts, notifications and escalations to drive task completion and resolve red-flag issues swiftly. Tailor and maintain consistent workflows that match your distinct business requirements.

Document Control: Your Trail to Transparency

Maintain a centralized document repository that reinforces standardization and version control, aligned with ISO 9001 standards. Elevate accountability and transparency while upholding a clear audit trail.

15%

increase in the identification and resolution of non-conformances

10%

improvement in customer satisfaction

The TenForce Approach: Simplifying Complex Processes

1

Plan

- Define precise internal quality benchmarks that align with relevant standards

- Identify key performance indicators (KPIs) to measure progress and success

- Track progress toward your goals to drive continuous improvement

- Develop documented procedures to ensure consistent and repeatable processes

2

Collect Quality Data

- Extract valuable insights from customer complaints and feedback

- Monitor data from audits and inspections to identify improvement opportunities

- Capture quality-related incidents and identify risks

- Collect all quality-related documents in a central, ISO 9001-compliant repository

3

Take Corrective and Preventive Action

- Conduct thorough assessments to identify and mitigate risks (FMEA, HACCP, FTA, ETA, etc.)

- Identify non-conformities and implement data driven CAPA plans

- Investigate the underlying causes of defects to take targeted action with root cause analysis

- Build change management strategies based on quality assessments and risk mitigation

- Assign tasks to the appropriate role, group, or individual to guarantee completion

4

Check, Analyze and Report

- Customize the segmentation and analysis of your quality data as per your requirements

- Regularly measure customer satisfaction to build a strong reputation

- Guarantee compliance by reporting your performance to official institutions

- Minimize your Cost of Quality (CoQ) by benchmarking your quality performance against established KPIs

5

Close the Loop

- Identify competence gaps in your workforce, then schedule and track training

- Keep your action plan on track through comprehensive and configurable overviews

- Manage your CAPA plans proactively to foster a culture of continuous improvement

- Inspect and audit your processes to continuously refine your quality strategy

The TenForce Quality Management Suite

Dive deeper into this topic

Silos to Synergy: Managing Safety and Quality Together

Juggling product quality and workplace safety can be quite a balancing act. That’s why so many EHSQ professionals have turned to Quality Management Software (QMS) and Environmental, Health, and Safety (EHS) software. Yet despite the overlap between them—both focus on compliance, reducing risks, and improving processes—these tools have traditionally operated in silos.

Now there’s a growing recognition that you can make your operations even more efficient and effective by integrating them.…

6 Challenges Leaders in Food Manufacturing Are Facing Today (& How to Tackle Them)

Being a leader in food manufacturing brings a number of challenges. From the ongoing scrutiny of the industry to emerging sustainability demands, there’s a lot to consider. We list six main problems food manufacturing leaders face and how to overcome them.

Challenge 1: Constant ScrutinyThe business of food manufacturing is directly related to public health. The tiniest mistake can have dire consequences. With lives on the line, it’s no surprise that regulations are tight and audits frequent.…

Putting Quality Management Centerfold

International Standards ISO 9000 and ISO 9001 describe the means and method of setting up a Quality Management System (QMS). What is not immediately obvious when reading these documents, is that they actually seek to help create a company culture to support the mission for better quality management, and not simply help to set up a QMS.

And it’s clear why: quality management no longer simply belongs to the quality assurance department or team.…

Your peers trust us

Our customers rely on TenForce to foster a proactive safety culture and drive continuous process improvement. The outcome? Increased team efficiency, reduced administrative burden, and significant cost savings due to fewer fines and incident-related downtime.

Book a demo

Curious to see how TenForce can make your workday easier? Book a demo, and we’ll show you what our EHSQ platform can do! One of our in-house experts will guide you through the ins and outs, showing you exactly how TenForce can tackle your challenges, whether it’s managing safety, streamlining compliance, or keeping quality in check.

So, choose a time that works for you, and let’s explore how TenForce fits into your day-to-day.

Ask us questions. Get clear answers. Share the recording with your colleagues.