Food Safety and Quality Management Software for F&B Leaders

Your comprehensive digital solution for quality, safety, and compliance

Overcoming food safety risks and quality control challenges

Confident compliance

Automate reporting to consistently meet industry standards (HACCP, FSMA, FDA, GMP) and avoid penalties.

Keep customers safe

Consistently deliver safe, high-quality products. Track defects, optimize quality control, and respond swiftly in the event of product recalls.

Strengthen brand integrity

Respond swiftly to customer feedback and proactively address concerns to build your brand reputation and build customer trust.

Maintain market agility

Avoid financial implications associated with re-inspections, recalls, brand damage, and customer loss. Minimize the cost of quality to maintain agility in a competitive market.

Protect your workers

Elevate safety protocols, identify and address risks, streamline incident reporting, and cultivate a robust safety culture.

Demonstrate sustainability

Implement resource-efficient practices, reduce environmental impact, and transparently communicate sustainability efforts.

Deliver high-quality products, preserve your brand integrity, and thrive in today’s competitive market

Food safety hazards, operational inefficiencies, shifting consumer demands, and the risk of non-compliance all threaten your brand's reputation and bottom line. TenForce is your digital toolkit for success. It centralizes data, streamlines workflows, and automates compliance.

Your recipe for reliable food safety management

Take a step-by-step approach

Customer Stories

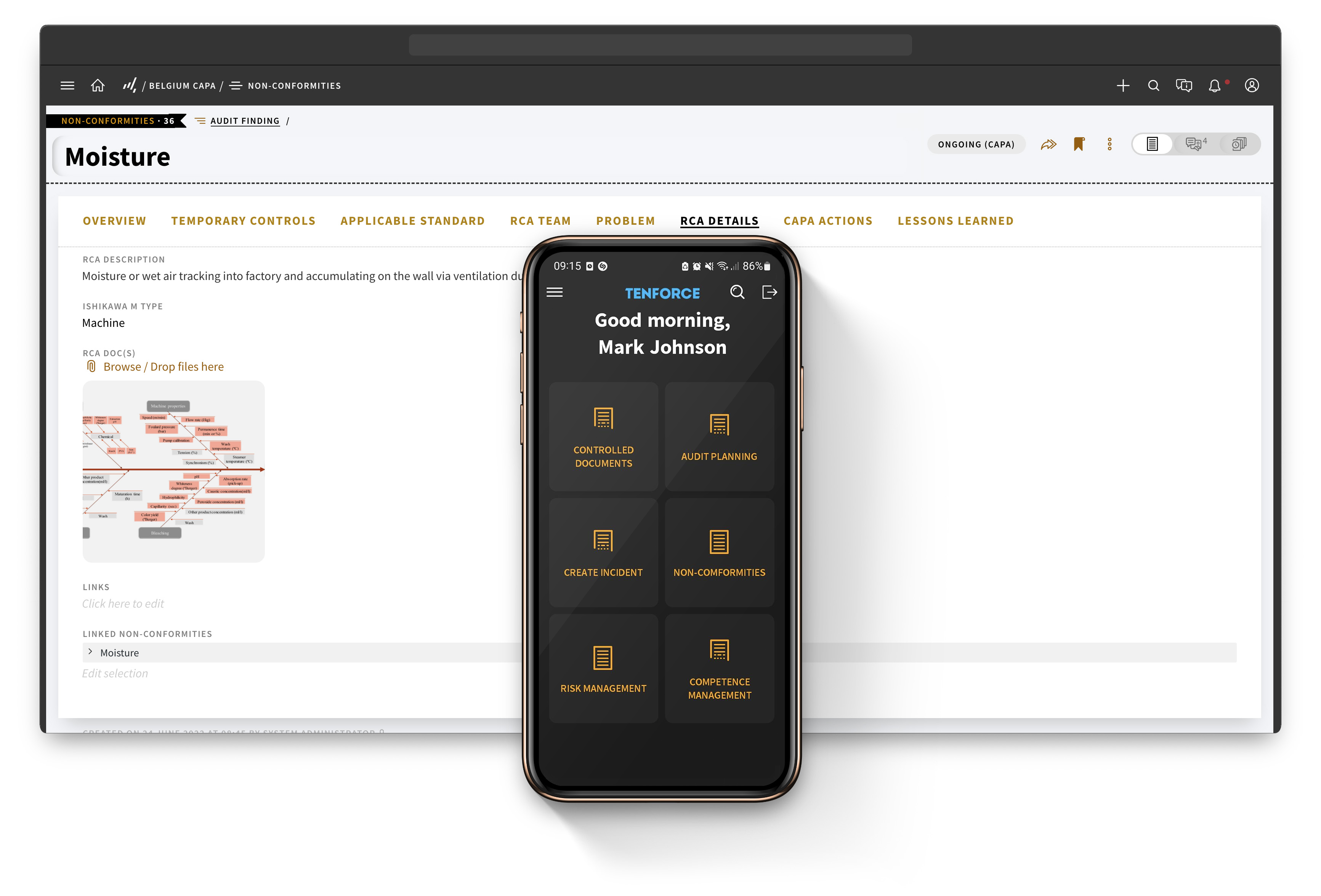

Using Technology to Streamline the CAPA Process Across the World

Discover how one of the world’s largest dairy companies ensures quality and safety from grass to glass across four continents.

Streamlined processes for increased profitability

Provide access to centralized, up-to-date records

Encourage collaboration between teams across multiple sites by giving them easy access to a centralized repository of up-to-date records, requirements, and critical food safety metrics.

Reduce risks and increase food safety

Monitor and manage safety, quality, and compliance data in real-time. Proactively mitigate risks by identifying food hazards before they escalate.

Streamline compliance

Improve compliance with centralized data, automated quality control processes, and digital checklists and forms tailored to your specific requirements.

15%

increase in the identification and resolution of non-conformances

10%

improvement in customer satisfaction

Dive deeper into this topic

6 Challenges Leaders in Food Manufacturing Are Facing Today (& How to Tackle Them)

Being a leader in food manufacturing brings a number of challenges. From the ongoing scrutiny of the industry to emerging sustainability demands, there’s a lot to consider. We list six main problems food manufacturing leaders face and how to overcome them.

Challenge 1: Constant ScrutinyThe business of food manufacturing is directly related to public health. The tiniest mistake can have dire consequences. With lives on the line, it’s no surprise that regulations are tight and audits frequent.…

Back to Food Safety Basics: HACCP Compliance

HACCP – Hazard Analysis Critical Control Point – should ring familiar in the ears of food professionals worldwide. A HACCP plan ensures food safety and includes risk analysis in the entire product lifecycle. Mandated by the FDA, an HACCP plan is more than just a regulatory requirement; it’s a crucial framework for safeguarding public health. Let’s get back to why it matters, and what it takes to make it effective.

The key ingredientsA good food safety plan involves analyzing hazards, putting preventive measures in place, monitoring procedures, taking corrective actions when necessary, verifying effectiveness, and maintaining quality documentation.…

Advice that Will Make You Rethink Leadership in Food Safety

We recently came across this article in Food Safety Magazine written by Gina R. Kramer, dealing with leadership in the Food Safety field. When reading it, a few nuggets of advice really stood out, which we’d love to share with you in this post.

Experience in the field is more valuable than a degreeWorking on the floor, or any place where the actual food you’re ensuring the safety of is being handled, can teach you more than you think.…

Your peers trust us

Our customers rely on TenForce to foster a proactive safety culture and drive continuous process improvement. The outcome? Increased team efficiency, reduced administrative burden, and significant cost savings due to fewer fines and incident-related downtime.

Book a demo

Curious to see how TenForce can make your workday easier? Book a demo, and we’ll show you what our EHSQ platform can do! One of our in-house experts will guide you through the ins and outs, showing you exactly how TenForce can tackle your challenges, whether it’s managing safety, streamlining compliance, or keeping quality in check.

So, choose a time that works for you, and let’s explore how TenForce fits into your day-to-day.

Ask us questions. Get clear answers. Share the recording with your colleagues.