Antwerp-Bruges: The Port that Runs on TenForce

The Port of Antwerp-Bruges is one of the world’s largest ports, and Europe’s biggest chemical cluster. Spanning 120 km², its docklands and industrial zones are home to more than 90 Seveso sites, all handling flammable, toxic, and pressurized substances under strict safety rules.[1]

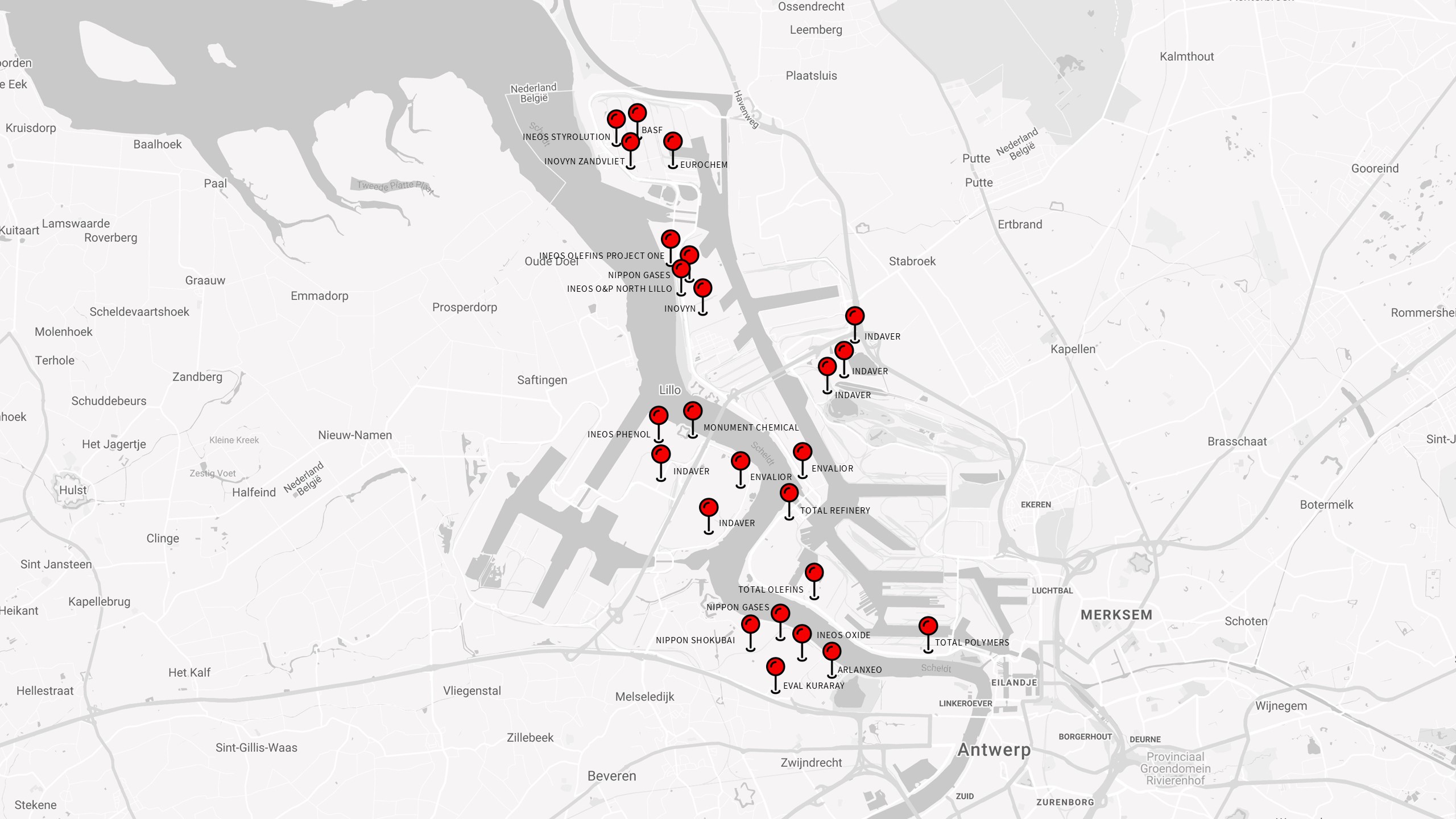

With over 1,400 companies on site — including long-time TenForce partners like BASF, INEOS, TotalEnergies, Indaver, Monument Chemical, Nippon Shokubai, and EuroChem — the port is a hub for high-risk operations like refining, polymer production, and waste incineration. [2] And they run on a massive scale. TotalEnergies’ Antwerp platform alone processes 338,000 barrels per day, making it one of Europe’s largest refineries.

Here, where the risks are high and the regulations are tighter, one small miss can lead to disaster. That’s why so many leading companies in the port rely on TenForce to keep safety actions on track.

From one site to 25+ and counting

We’ve grown up alongside the Port of Antwerp-Bruges. It isn’t just one of our markets; it’s where our EHSQ story began.

Back in 2006, the team at Eval (Kuraray’s Zwijndrecht plant) were struggling with too much process overhead and not enough visibility. They needed a better way to track safety-critical actions and manage daily operations.

At the time, we weren’t an EHSQ company. But our software was helping teams manage projects and actions by digitizing follow-ups and automating workflows.

During a demo, Eval saw the potential for TenForce to manage their health and safety processes. Guided by their knowledge of their business processes, we added a few custom fields on the spot. That flexibility sealed the deal.

What began as incident management quickly grew to cover audits, MoC, shift handovers, permits, and contractor management. Eval became our first EHSQ client, and they didn’t keep it to themselves.

At safety meetups across the port, Eval shared TenForce with neighbors like Nippon Shokubai and Monument Chemical. By 2016, we were hosting our own sessions in Kallo to help EHS professionals exchange ideas and experiences.

Today, we support 25+ facilities across the Port of Antwerp-Bruges with a full suite of EHSQ modules.

Why safety leaders in the port choose TenForce

The port supports 164,000 jobs and moves over 300 chemicals through 1,000 km of pipelines.[3] Keeping that many people safe, all in one of the world’s most complex industrial zones, is no small feat.

Companies here face a unique set of safety and operational challenges:

- High-risk processes like steam cracking, incineration, and chemical storage

- Hazardous materials, including VOCs and yellow phosphorus

- High contractor turnover and rotating workforces

- Complex logistics involving rail, road, water, and pipeline transport

- Strict and evolving regulations from regional and national authorities

- Shared responsibility zones, where safety depends on coordination across companies

Failures mean health risks, environmental damage, and costly downtime. That’s why companies turn to TenForce. Our EHSQ platform helps them:

- Make safety actions traceable

- Spot and prevent incidents early

- Standardize processes across teams and sites

- Stay compliant and audit-ready

We help keep complex operations under control and people out of harm’s way.

TenForce in action across the port

More than 25 sites across the Port of Antwerp-Bruges use TenForce to manage safety, risk, and compliance.

[Click the map to zoom in]

Here’s how a few of them put TenForce to work on site:

INEOS: A long-term partner driving safety across the port

INEOS is one of our longest-standing partners in the Port of Antwerp-Bruges, with sites in Lillo, Zwijndrecht, Kallo, and Zandvliet, including those operated by INEOS Inovyn. Each location has its own needs, and TenForce helps support them all with tailored EHSQ setups.

From Incident Management to Management of Change, contractor pre-approval to workwear management, TenForce helps INEOS teams handle both the day-to-day and high-risk tasks.

By leaving behind disconnected legacy tools, INEOS now benefits from:

- Clearer processes across teams and locations

- Real-time insight into incidents, changes, and safety tasks

- Fewer bottlenecks and less paperwork, thanks to automated workflows

“With TenForce, there’s less paperwork, more transparency, and everything is clearer for everyone involved. The system keeps up with our needs and adapts when necessary—it works for us, not the other way around.”

Bert Schietekat, Process Safety Advisor at INEOS Inovyn Antwerp

We’re proud to be INEOS’s preferred global supplier for HSEQ and Operational Risk Management. And to support ESG reporting across the group, with consistent, consolidated data, no matter the site, country, or business unit.

Learn more about how INEOS teams use TenForce:

- How Inovyn reports an incident in less than 10 seconds

- Inovyn’s digital-first approach to managing change

Indaver: One system for safer waste handling

Handling high-risk waste is anything but routine. From categorizing materials to tracking shipments, there’s a lot of manual handling, and no room for error. Indaver’s teams need to spot issues fast, make decisions quickly, and take action on the spot. That requires one clear, consistent way to report incidents and near misses, no matter the site or local regulations.

That’s why they chose TenForce. With a standardized approach to incident management rolled out across Belgium and the Netherlands, every event is now logged, tracked, and followed up the same way, making it easier to spot risks, share lessons, and prevent future incidents across the group.

Read how Indaver improved incident tracking with TenForce.

Monument Chemical: One platform across five sites

Monument Chemical’s specialty chemicals plant in Antwerp, along with sister sites in the U.S., used to manage safety with spreadsheets. Now, with TenForce, they use one shared platform for incident, change, and action management from Antwerp to Texas.

Every site tracks incidents the same way, follows up automatically on non-conformities, and manages change with full visibility. The result?

- 50% fewer consequential incidents

- 61% more actions followed up

“Transparency has significantly improved. Action follow-ups from incidents or audits are now structured and easy to track—nothing falls through the cracks.”

Peter Jacobs, EH&S Delivery Leader, Monument Chemical

See exactly how Monument Chemical did it.

EuroChem: Staying in control of change

EuroChem’s Antwerp plant plays a key role in their global fertilizer production. With complex chemical processes, managing operational risk is non-negotiable. With TenForce, their teams manage incidents and MoC in one platform. So, whether it’s a near-miss or a major modification, everything gets logged, reviewed, and followed up with the same structure and accountability.

With built-in workflows, automated alerts, and a clear audit trail, EuroChem’s teams have the visibility they need to act fast, stay compliant, and keep operations running safely.

Ready to join your peers in the port?

More than 25 sites across the Port of Antwerp-Bruges already rely on TenForce to run safer, more efficient operations—from incident logging to permit-to-work, contractor safety to ESG reporting.

If you’re in the port, we’re likely already on your neighbor’s site—or your contractor’s phone.

With TenForce, you get:

- A flexible, modular system that grows with your needs

- Tools you can use on site and in the field

- Standardized processes that reduce errors

- Real-time insights for faster decisions

- A partner that knows your industry and your neighborhood

Whether you’re just getting started or ready to streamline across multiple plants, we’re here to help.

Let’s talk about what TenForce can do for your site.

Sources

[1] https://www.portofantwerpbruges.com/en/emergency-plan

[2] https://newsroom.portofantwerpbruges.com/annual-figures-for-port-of-antwerp-bruges-show-growth-despite-challenging-times

[3] https://newsroom.portofantwerpbruges.com/annual-figures-for-port-of-antwerp-bruges-show-growth-despite-challenging-times