AI Revolution Driving Operational Excellence in Manufacturing

In the ever-evolving landscape of manufacturing, increasingly complex processes can breed inefficiency. The result? A nosedive in productivity. Not to mention an alarming rise in potential hazards.

Enter EHSQ (Environmental, Health, Safety, and Quality) software, along with a much-talked-about game changer – Artificial Intelligence (AI).

Together they offer the promise of higher production yields, reduced operational costs, improved product quality, and increased competitiveness in the global market.

But how exactly? And, crucially, how can we ensure that humanity remains at the heart of it all?

The Foundations of AI in Manufacturing

Data-driven intelligence is the foundation of AI. It paves the way for the various AI concepts that are redefining production processes, including:

Machine Learning (ML)

ML algorithms enable machines to learn from data without explicit programming. In manufacturing, that means optimizing production processes, identifying anomalies in equipment behavior, and predicting maintenance needs. It’s all about minimizing downtime and reducing safety risks.

Computer Vision

Computer vision enables machines to interpret and understand visual information. In quality control, computer vision automatically detects defects in products. That way, only high-quality items reach the market. And, on the shopfloor it shines a light on unsafe practices and non-compliance with safety protocols.

Natural Language Processing (NLP)

NLP enables machines to comprehend and process human language. Instead of scrabbing for a pen and paper, workers can simply describe an incident – hands-free. NLP takes care of the rest, translating their words into structured data that the Incident Management software understands.

Digital Twin

By analyzing data from the digital twin, manufacturers can swiftly pinpoint areas where product or process performance deviates from desired standards. This insight empowers informed decision-making, facilitating improvements in product quality and overall operational efficiency.

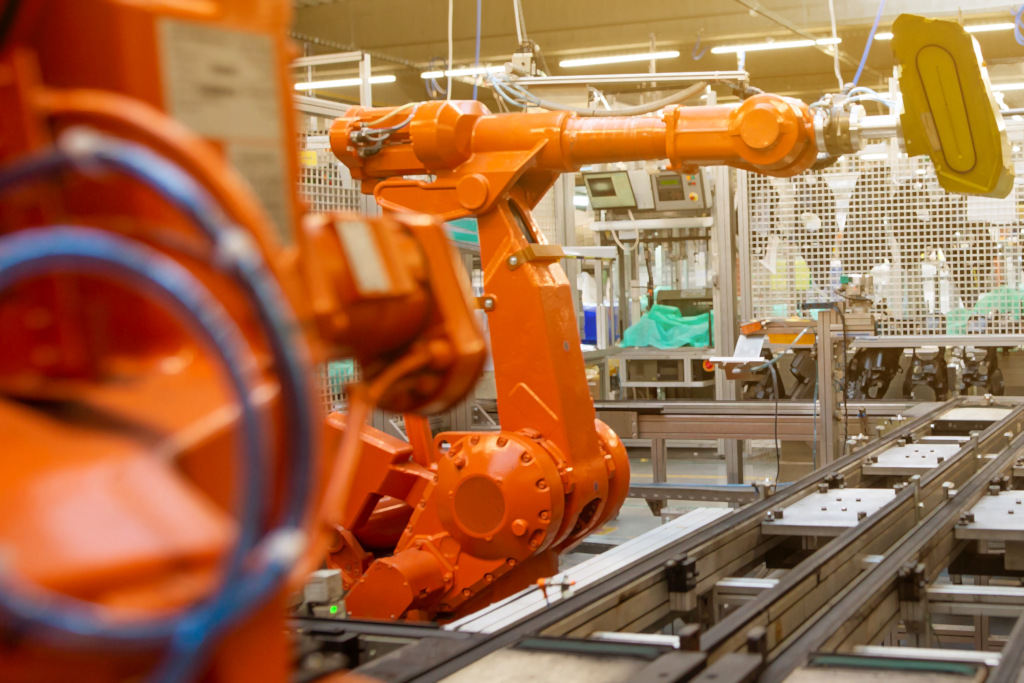

Robotics

Autonomous objects, such as autonomous mobile robots (AMRs) can perform tasks without human intervention. Think material handling, tracking inventory, and facility inspections.

These robots reduce human exposure to hazardous environments and eliminate human errors. Plus, they’re masters of repetitive tasks – completing them with precision and speed. This frees up human workers to tackle tasks that demand creativity and problem-solving skills.

The Benefits of AI for EHSQ Processes

Building upon our exploration of AI’s diverse applications in manufacturing, let’s now turn our attention to how AI is making waves in EHSQ processes:

- Detect Hazards: AI-powered cameras and sensors can monitor the manufacturing floor to detect hazards and trigger safety protocols. They catch things like missing safety gear, unsafe practices, and hazardous substances.

- Increase Efficiency: AI streamlines repetitive EHSQ workflows, freeing workers to focus on crucial tasks and making operations run smoother and faster.

- Implement Proactive Measures: AI rapidly processes vast data, offering insights for data-driven decision-making. By analyzing historical data, it helps manufacturers spot trends and swoop in with proactive measures to keep accidents in check.

- Reduce Downtime: AI’s real-time analysis of machine data anticipates equipment failures. Predictive maintenance detects anomalies, foreshadowing potential failures, minimizing downtime, and boosting production.

- Manage Environmental Monitoring: AI-driven sensors can track energy consumption, emissions, and waste generation. This data helps manufacturers optimize resource usage, comply with environmental regulations, and reduce their carbon footprint.

- Comply with Regulations: AI can continuously analyze new laws and regulations, updating and adapting procedures and protocols to ensure ongoing compliance.

- Improve Quality Control: Machine vision technologies can detect defects, inconsistencies, or deviations with high precision. This ensures market-ready, safe products, reducing recalls and strengthening brand reputation.

So, that was a whistle-stop tour of how AI plays a role in EHSQ processes. But what about TenForce’s part in all of this? To find out, let’s take a closer look at AI-PROFICIENT.

AI-PROFICIENT: Unveiling Manufacturing’s Tomorrow through Research and Development

AI-PROFICIENT is a collaborative effort among research institutions and technology providers aimed at combining human expertise with AI, IIoT (Industrial Internet of Things), and AR (Augmented Reality) technology to unlock new levels of plant productivity across the entire EU manufacturing industry.

The project offers early fault detection and quality issue prediction, digital twin-based simulation, transparent decision-making, and personalized shop floor assistance with extended reality and conversational interfaces for connected workers.

AI-PROFICIENT empowers plant operators with decision support, automation capabilities, and valuable insights while ensuring that humans remain in charge. The ultimate goal is to enhance manufacturing processes, targeting a 10% increase in Overall Production Efficiency (OPE) and a 50% decrease in low-quality product output.

AI and Wearable Technology: Reducing Errors in Chemical Production

One of the major achievements of AI-PROFICIENT is the successful deployment of AI technology in real-world production environments.

At a Belgian chemical plant, TenForce has combined EHSQ software, image recognition, and AI-enabled algorithms to optimize raw material use, helping operators overcome the challenges they face when manually adding additives to feeders.

Due to inconsistent, damaged, or absent labels, and operator fatigue, the process was error-prone, with the potential for operators to pour the wrong additive into feeders, leading to significant product loss.

TenForce implemented a solution where operators utilize wearable devices to scan labels. ML and AI interpret labels, comparing them with the feeder requirements and supplying immediate feedback to the operator.

This practical application of AI-PROFICIENT has significantly reduced the risk of human error and the associated product loss, highlighting the potential of ML/AI to overcome operational challenges in continuous chemical production

Innovations on the Horizon

And that’s not all AI-PROFICIENT has up its sleeve, the R&D initiative is closing in on:

- A solution that combines transparent decision-making, quality analysis tools, and Explainable AI to improve products, optimize processes, and gain a competitive edge.

- A ground-up ethics approach that adapts to continually evolving guidance.

- A root cause analysis tool that utilizes deep semi-supervised anomaly detection and human feedback.

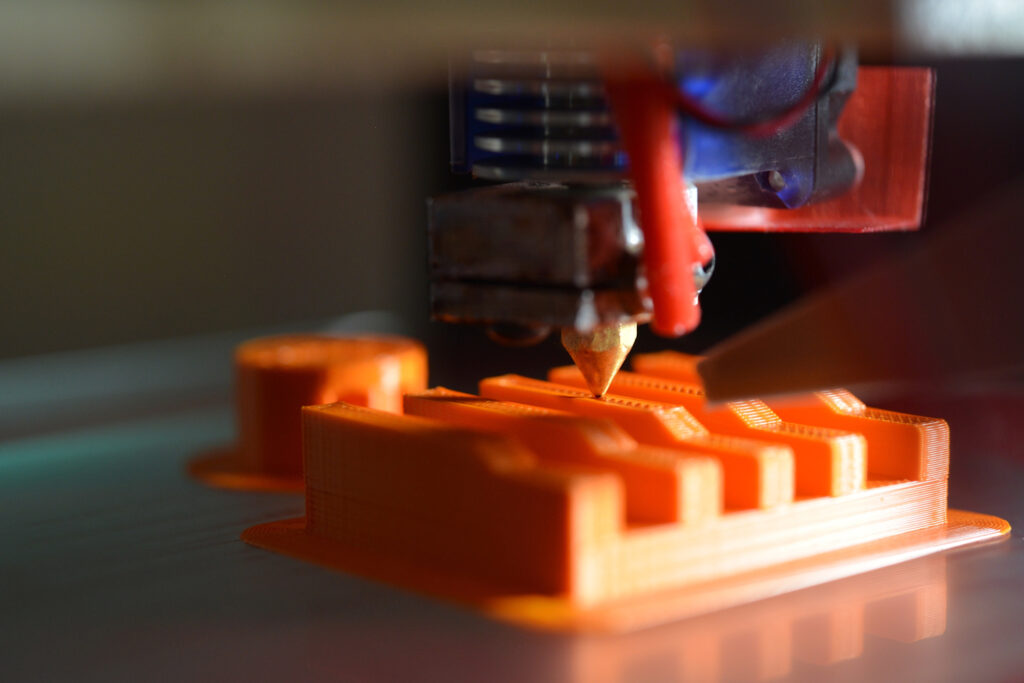

- A use case specifically focused on polymer extrusion and laser metal decomposition-based additive manufacturing.

The Future of Manufacturing: Blending Human Expertise with AI

So, there you have it—AI’s integration into the manufacturing sector holds immense promise. From monitoring the shop floor to lending a helping hand in hazard detection and quality control, it seems that AI is here to stay.

But there’s no need to panic. It’s not about replacing humans. The AI-PROFICIENT project provides a tangible example of how AI and human expertise can work in tandem, where wearable technology and intelligent algorithms combine to mitigate errors and boost operational efficiency.

As we look to the future, it becomes clear that AI’s role is that of an augmenter, not a disruptor. It amplifies human capabilities, fostering improved production efficiency, superior product quality, and heightened safety standards. In this trajectory, AI stands as a partner to EHSQ processes and solutions.

Get in touch to find out how you can integrate AI with your EHSQ processes.