How To Master Shift Management: Strategies for Success

Did you know that a staggering 40% of plant incidents occur during critical periods like start-up, shutdown, and shift handovers [AFPM Research]? Or that miscommunication during shift handovers is to blame for nearly every other incident in the process industry? These alarming statistics underscore the vital importance of shift management.

Shift handovers often suffer from inadequate knowledge transfer, leaving incoming shifts with an imperfect understanding of events that unfolded in previous shifts. In safety-critical environments, where the consequences of errors can be severe, concisely conducting shift handovers is paramount in mitigating risks.

Discover the secrets of successful shift management as we work through the complexities of shift handovers. Gain a deep understanding of the importance of shift handovers, explore the common challenges faced by workers, and unlock practical strategies to enhance the shift handover process.

What Happens During a Shift Handover?

As you know, shift-bound work is a system of rotating schedules commonly found in continuous process operations, such as manufacturing. At the heart of shift work lies the handover process between teams during shift changeovers.

The transfer of knowledge from outgoing to incoming staff, known as shift handover, is crucial for maintaining smooth work practices. Typically, the outgoing team gathers task-related details and shares them with the incoming team through written logs or face-to-face briefings. The incoming team then double-checks this information to ensure a seamless continuation of tasks and responsibilities.

Why Do Shift Handovers Matter?

We’ve touched upon the significance of managing shift handovers correctly in the past, but it’s worth reiterating just how crucial effective shift management truly is.

- Firstly, it ensures that task-related information is communicated accurately and reliably as teams switch shifts. This seamless transfer of information is essential for maintaining a safe work environment.

- Secondly, shift handovers offer a chance for learning, which is often overlooked in shift work settings. By sharing insights and experiences, teams can foster continuous improvement and enhance overall operations.

What Happens When Shift Handovers Go Wrong?

Now, let’s delve into the consequences of mishandled shift handovers. The statistics tell us that incidents disproportionally occur directly following the handovers. To demonstrate the severe consequences of inadequate shift handovers, let’s examine four real-life industrial incidents:

- Dupont La Porte Toxic Chemical Leak, 2014. A sequence of miscommunications during shift changes led to the release of 24,000 pounds of methyl mercaptan, resulting in the loss of four lives and a penalty of $237,000.

- BP Texas City Refinery Explosion, 2005. Inadequate communication of crucial instructions concerning a startup procedure during a shift change led to explosions and fires that killed 15 people, injured 180, and resulted in financial losses exceeding $1.5 billion.

- Buncefield Fire, 2005. Deficiencies in shift handovers and failure to capture information throughout the full shift created confusion and led to a fire that resulted in 43 injuries.

- Esso Longford Gas Explosion, 1998. Ineffective handovers and logbook entries, lack of specified handover requirements, and failure to adhere to basic operating practices, including those about shift handover, contributed to the incident which killed two workers.

These industrial accidents, where failures of communication at shift handover have been identified as contributory factors, highlight the importance of proper shift management, especially in high-risk domains. But what makes shift handovers so difficult to get right?

What Challenges Do Shift Handovers Pose?

Operators face a multitude of challenges during shift handovers, including issues such as fatigue, time constraints, and communication barriers.

However, one of their biggest challenges relates to documentation issues and the subsequent inadequate transfer of knowledge. Despite the ongoing trend toward digitalization, paper remains the preferred tool for handling shift handovers. This reliance on paper poses certain problems, including:

- Double or triple recording of information

- Errors and issues with legibility

- Limited visibility due to the presence of only a single copy

- Missing information due to lack of standardization

How Can Shift Handovers Be Improved?

Addressing these challenges requires implementing clear communication protocols, standardized documentation practices, adequate time allocation for handovers, and promoting a culture of knowledge sharing and collaboration.

During shift handovers, it is essential that:

- Verbal and written communication methods are used to convey information effectively.

- Incoming and outgoing shifts actively participate.

- The process is based on the requirements of the incoming staff.

- Sufficient time and resources are allocated to ensure accurate communication.

Given the proven importance of effective communication at shift handover, organizations should give this activity a high priority and take steps to improve the process, such as:

- Identifying higher-risk handovers and giving them extra attention.

- Developing workforce communication skills to enhance the handover process.

- Emphasizing the importance of shift handover as a critical aspect of operations.

- Providing clear procedures for conducting shift handovers and setting minimum standards.

- Planning maintenance work to be completed within a single shift whenever possible.

- Paying special attention to handovers that occur after staff members’ lengthy absences, during plant maintenance, during deviations from normal working conditions, and when experienced and inexperienced staff are involved in the handover.

- Designing support equipment, such as logs and computer displays, to meet the specific needs of operators.

- Including shift handovers in the safety-critical topics supervised and auditing them periodically.

What Role Can EHSQ Software Play?

Relying on log books filled with endless pages of notes makes it difficult to find critical information, and spreadsheets do little to alleviate this challenge. Relying solely on verbal handovers without written documentation leaves room for miscommunications and misinterpretations.

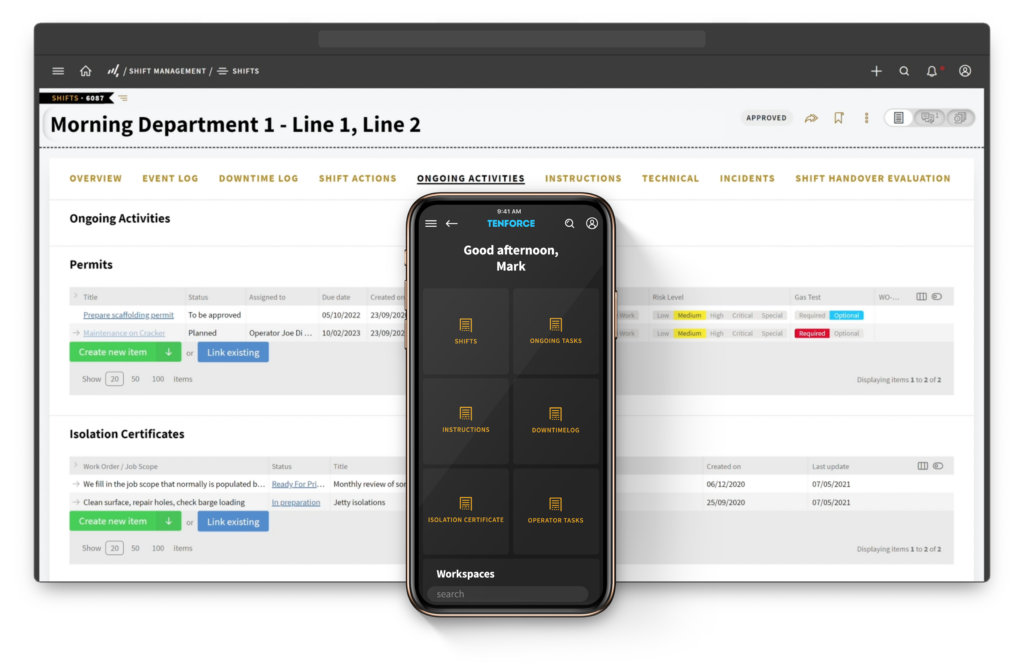

Fortunately, there is a solution: TenForce Shift Management. Our software automates the shift handover process, making data easily accessible, extractable, interpretable, and analyzable, eliminating the hassles of traditional methods. Implementing this software ensures a solid foundation for successful shift management, and presents a myriad of benefits including promoting full employee engagement, and harnessing the benefits of centralized data.

Need more convincing? Watch our webinar to discover how a digital solution can revolutionize your shift management practices. Plus, don’t forget to download our eBook for a step-by-step guide to the lean approach to shift management. Take the first step towards improving your shift handovers today!