Elisa IndustrIQ and TenForce: Working Together to Make Intelligent Manufacturing a Reality

From the era of water and steam power to the advent of Industry 4.0 – have you ever wondered about how manufacturing has evolved? Well, you’re in the right place! In this blog post, we will share how our alliance with Elisa IndustrIQ is turning intelligent manufacturing into a tangible reality.

Together with CalcuQuote, camLine, and SedApta, TenForce sits within the parent company of Elisa IndustrIQ, an innovative division of the Finnish telecom giant, Elisa Corporation. We’re blazing the trail toward a sustainable future through digitalization, combining our knowledge and expertise to build a complete digital ecosystem for the manufacturing industry.

Join us as we explore how its four pillars combine to reshape the manufacturing world.

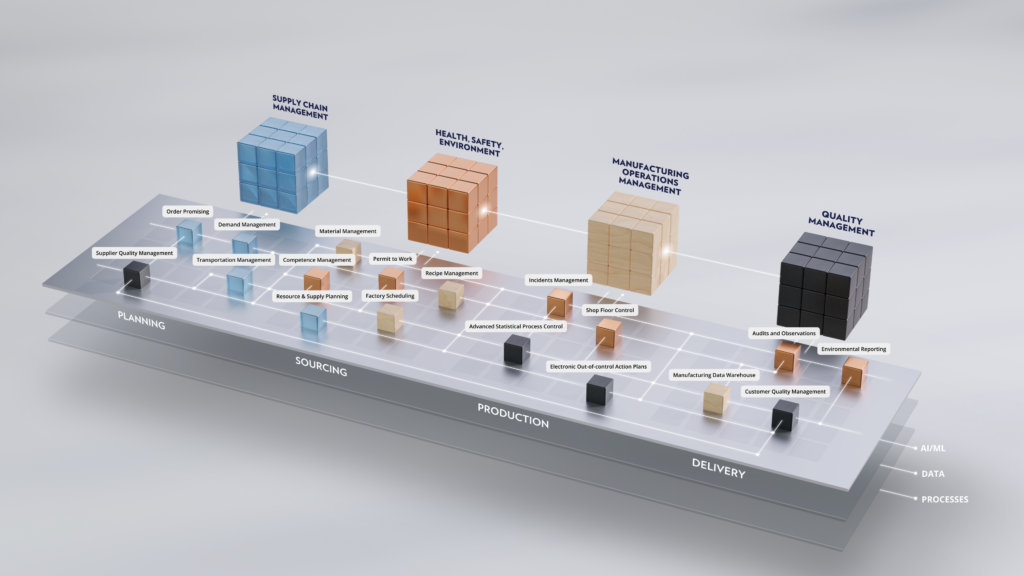

A Modular Digital Ecosystem

Elisa IndustrIQ’s modular software optimizes manufacturing processes to empower decision-making at all levels from top management to the factory floor.

Focused on four core areas — supply chain management, manufacturing operations, quality management, and EHSQ (Environment, Health, Safety, and Quality) solutions — this modular software supports various industry verticals, including food and beverage, high-tech and electronics, machinery and equipment, battery manufacturing, and chemicals.

With each module implementation, you build a more comprehensive view of your entire supply chain and beyond, gaining a deeper understanding of your operations. This flexible, step-by-step approach enables you to address one issue at a time.

Health, Safety and Environment

Let’s begin with Health, Safety and Environment – our area of expertise! With modules dedicated to risk management, incident management, environment management, permit to work, audits and inspections, and more besides, our software offers significant advantages for EHS (Environmental, Health, and Safety) processes in your organization. Here are five reasons to take this first step toward manufacturing intelligence:

- Boost Your Operational Efficiency: Streamline and automate EHS processes to reduce administrative burdens, drive cost savings, and increase productivity in your operations.

- Take Control of Risk Mitigation: Centralize your data for efficient EHS management. Utilize comprehensive analytics and reporting to identify trends, patterns, and areas for improvement, helping you to proactively mitigate risks.

- Prioritize Workplace Safety: Support incident management by promptly reporting, investigating, and resolving incidents. Mitigate risks and create a safer workplace for your employees.

- Ease Compliance Burdens: Achieve regulatory compliance, ensuring the well-being of your employees and the environment. Reduce the risk of penalties and build a strong reputation for responsible and sustainable business practices.

- Foster a Culture of Continuous Improvement: Promote effective communication and collaboration across your organization by sharing safety protocols and best practices. Make data-driven decisions to drive a culture of continuous improvement.

For more information about our EHSQ software solutions, visit our website.

Quality Management

As you begin your journey towards intelligent manufacturing, incorporating Quality Management into your digitalization toolkit will bring you closer to achieving your goals. Modules dedicated to advanced statistical process control, supplier quality management, customer quality management and electronic out-of-control action plans can help you:

- Establish Robust Quality Control: Strengthen your quality control processes across the manufacturing lifecycle. Enforce strict standards through thorough inspections, audits, and metric tracking to ensure unwavering product quality and prevent costly rework or recalls.

- Enable Continuous Quality Improvement Possible: Enhance real-time visibility and traceability of quality data to monitor trends, identify potential issues, and take swift proactive measures. Improve root cause analysis and make data-driven decisions.

- Accelerate the Resolution of Quality Issues: Automate workflows, foster cross-functional collaboration, and improve communication across teams to expedite the resolution of quality issues and accelerate corrective actions, ensuring swift and effective problem-solving.

- Reduce Customer Complaints: Utilize advanced analytics and reporting tools to identify patterns, trends, and improvement opportunities. Empower your team to take proactive quality initiatives to reduce customer complaints and enhance overall product quality.

- Drive Customer Satisfaction: Optimize your quality management processes to boost customer loyalty and enhance your reputation.

Supply Chain Management

As you continue your journey towards manufacturing intelligence, incorporating Supply Chain Management into your digitalization strategy marks a significant leap towards achieving your goals. With demand management, inventory management, quoting and purchasing automation, transportation management, material supply planning, and plenty more besides, you can:

- Accelerate Your Operations: Streamline and automate your supply chain processes, reducing lead times and optimizing inventory levels for increased efficiency and improved cost management.

- Uncover Bottlenecks and Disruptions: Gain real-time visibility of your entire supply chain. Track and trace materials, monitor supplier performance, and swiftly identify potential bottlenecks or disruptions.

- Stay Agile in the Market: Foster seamless collaboration among suppliers, manufacturers, and distributors. Enable faster decision-making, minimize errors, and proactively solve problems, enhancing your responsiveness to ever-changing market demands.

- Optimize Your Supply Chain Strategies: Leverage data-driven insights, advanced analytics, and reporting to identify areas for improvement. Make informed decisions to optimize your supply chain strategies, reduce risks, and elevate customer satisfaction.

- Gain a Competitive Edge: Enhance visibility, foster collaboration, and make data-driven decisions to improve overall performance, giving you a competitive edge in the market.

Manufacturing Operations

The Manufacturing Operations module completes the digital ecosystem for manufacturing. With various modules, including master data management, recipe management, factory scheduling, shop floor control, material management, carrier management, asset management, and maintenance management, you can:

- Supercharge Your Productivity: Monitor your production activities to track key performance indicators, swiftly identify bottlenecks, and proactively resolve issues. Enhance operational efficiency, minimize downtime, and maximize productivity.

- Eliminate Manual Errors: Streamline workflows through automation and standardization, reducing manual errors and ensuring consistent processes. Boost product quality, minimize rework, and delight your customers with improved satisfaction.

- Reduce Costs and Boost Profitability: Fine-tune scheduling and capacity planning for optimal resource utilization. Maximize the efficiency of equipment, labor, and materials to reduce costs and increase profitability.

- Foster Agile Problem Solving: Enhance collaboration and communication between departments and teams. Encourage seamless information sharing to facilitate faster decision-making.

- Achieve Operational Excellence: Optimize manufacturing operations to unlock enhanced visibility, streamlined workflows, and optimized resource utilization. Propel your organization towards operational excellence in a competitive market.

From EHSQ Management to Transforming Your Entire Manufacturing Operations

By working with Elisa IndustrIQ we gain access to a complete digital ecosystem designed to enhance every aspect of your manufacturing processes. So, once you’ve got your EHSQ management on track with our software, it will be easy to make improvements in your supply chain, manufacturing operations, and quality management.

It’s all about taking your manufacturing game to the next level!

Keen to make intelligent manufacturing a reality at your organization? Let’s have a conversation!